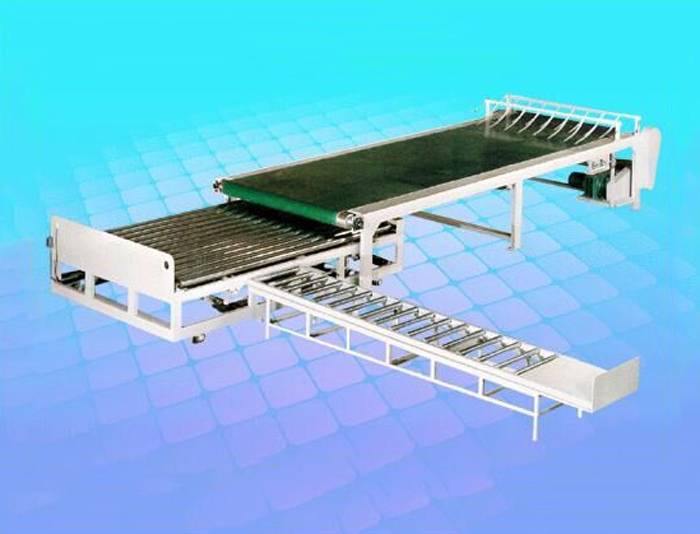

OEM Manufacturer Double Facer Machine For Corrugated Baord - Double facer SM-10 – Xinguang

OEM Manufacturer Double Facer Machine For Corrugated Baord - Double facer SM-10 – Xinguang Detail:

※Structural features:

★Heating plate surface by grinding treatment, hot plate width 600mm, a total of 12 heating plate and cooling 4 m。

★Heating plate with a container board production, in line with national standards for a class pressure vessel, with pressure vessel certificate and inspection certificate。

★Hot plate with intensive gravitational roll structure. Roll adopt pneumatic lifting.

★Heating plate heat transfer pipe temperature control sub-four-segment, with a temperature display.

★on cotton use two-cylinder S type cotton belt with the tensioning device.

★lower belt adopt pneumatic tensioning.

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output。

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam。

※Technical parameters:

1、temperature requirement:160—200℃ steam pressure:0.8-1.3Mpa

2、air source pressure:0.6—0.9Mpa

3、Cooling stereotypes length:4m Heating plate quantity:12 pieces

4、hydraulic system pressure:6—8Mpa

※Roller diameter parameters:

1、upper drive rubber roller diameter:¢475mm lower drive rubber roller diameter:¢350mm Wear rubber Outsourcing

2、Former follower with roller diameter:¢176mm back setting belt driven roller diameter:¢176mm

3、Platen roller:¢85mm Setting roller diameter:¢86mm

4、upper belt tension roller diameter:¢155mm upper roll diameter with detuning:¢124mm

5、Lower belt tension roller diameter:¢130mm Entrusted with the roll diameter lower belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated

※Powered motor parameters:

1、Main drive motor power:22KW 380V 50Hz Continuous (S1) working standard

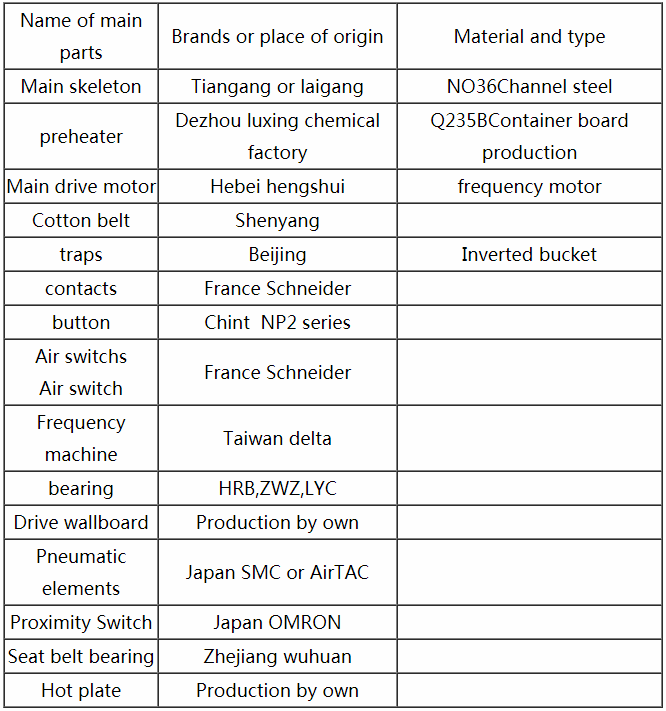

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for OEM Manufacturer Double Facer Machine For Corrugated Baord - Double facer SM-10 – Xinguang , The product will supply to all over the world, such as: Czech republic, Bandung, Rome, Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.Thanks.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!