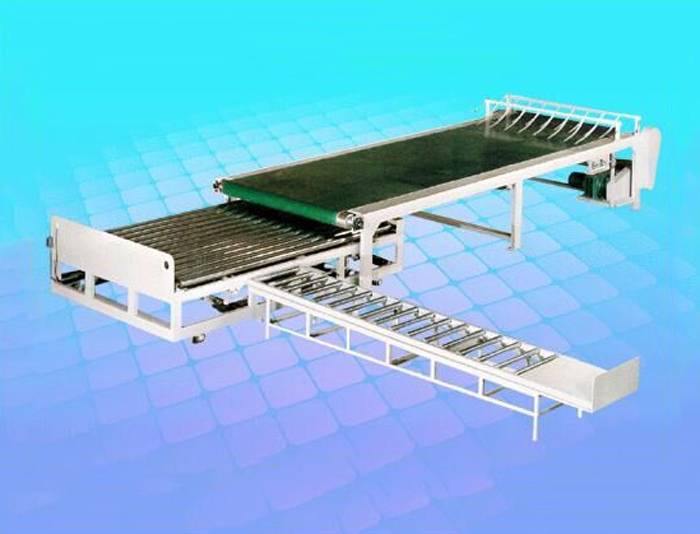

Manufactur standard Corrugated Paper Single Facer Macine - Single facer SF-320C – Xinguang

Manufactur standard Corrugated Paper Single Facer Macine - Single facer SF-320C – Xinguang Detail:

※Structural features:

★adopt hood suction structure,matched high pressure powerful fan. Gas supply and electrical control cabinet to focus on the same operation, the operating side full cover closed.

★High quality resin sand casting,wall thickness 200mm。Adopt independent gear box, Universal joint transmission structure.

★install the lifting trolley on the conveyor bridge,Need to use the car will tile roll assembly and pressure roller, such as convenient and quick.

★Glue roller unit structure with the overall relocation,Maintenance can sway the machine at the overall maintenance,improve the working efficiency。

★The humidity control apparatus equipped with a spray, so flute type to maintain good stability of deformation, avoid dry。

★Automatic circulation system for glue, two-cylinder pneumatic gluing device, with good cushioning effect.

★Glue department using integrated slide structure,Glue roller surface after grinding engraved with 25 lines and pit-style textured hard chrome plating.

★corrugated roller adopt tungsten carbide dealing,diameter of the main corrugated roller¢ 320mm,Quenched→rough car→bore fine boring→shaft head shrunk-on→welding → tempering to stress→fine cars→coarse grinding→IF quenching→CNC grinding machine grinding→tungsten carbide dealing,hardness of surface is HV58degrees。

★Active force variable frequency motor drive, energy efficient, low failure rate.

★Glue wide electric adjust to changes in the width of the paper used。

★Amount of glue size with electric adjustment, touch screen display and operation of the encoder transmission coating gap, high accuracy。

★Power and operating parts with a safety net to ensure the safety of personnel in the operation of machinery

※Technical parameters:

1、effective width:1400mm-2200mm

2、operate direction:left or right(Determined in accordance with the customer’s facility)

3、design speed:150m/min

4、range of temperature:160—180℃

5、air source:0.4—0.9Mpa

6、steam pressure:0.8—1.3Mpa

7、equipment:Lmx3.5*Wmx1.7*Hmx2.2

※Roller diameter parameters:

1、corrugated roller:up¢313mm down¢316mm pressure roller:¢320mm

2 、glue roller:¢240mm fixed paste roller: ¢140mm preheat roller:¢402mm

※Powered motor parameters:

1、main frequency drive motor:18.5KW rated voltage:380V 50Hz Continuous (S1) working standard

2、suction motor:11KW rated voltage:380V 50Hz Continuous (S1) working standard

3、glue reducer:100W rated voltage:380V 50Hz Continuous (S2) working standard

4、glue adjusting motor:100W*2 rated voltage:380V 50Hz short(S2) working standard

5、glue pump motor:2.2KW rated voltage:380V 50Hz Continuous (S1)working standard

※Auxiliary equipment:

1、Special pulley crane configuration tile roll maintenance, convenient to use when maintenance tile roll, and fast。

2、Configuring an external guide pulley crane to lengthen the trip, in order to successfully remove the line outside the repair parts。

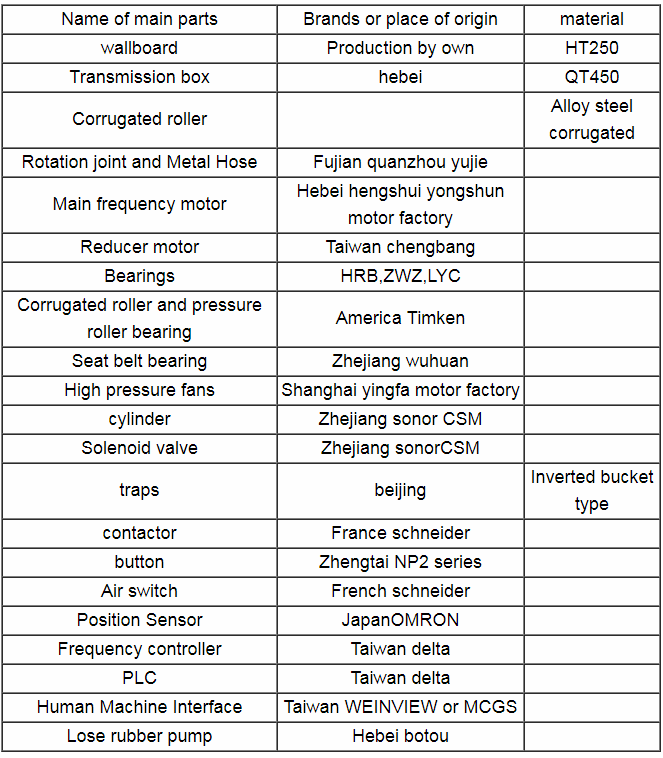

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for Manufactur standard Corrugated Paper Single Facer Macine - Single facer SF-320C – Xinguang , The product will supply to all over the world, such as: Argentina, Nepal, Malaysia, With the spirit of "high quality is our company's life; good reputation is our root", we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.