Factory wholesale Manual Operate Corrugated Sheet Gluer - Glue machine GM-20 – Xinguang

Factory wholesale Manual Operate Corrugated Sheet Gluer - Glue machine GM-20 – Xinguang Detail:

※Structural features:

★after quenched of the glue roller surface,the hole machining, surface grinding and doing balancing engraved anilox pit type, coating evenly, less consumption of plastic

★glue roller turns is controlled by the frequency motor,by inverter control ensures glue roller line speed synchronous machine with double machine,they can operate independently。

★electric adjustment display the glue amount。Automatic cycle for glue, glue avoid sedimentation, viscosity stability。

★Pneumatic structure platen gap by electric tuning。On the next floor are made independent variable frequency motor drive。

★take the speed signal of the double facer,so as to synchronous operation with it. Man-machine interface display, easy operation

★amount of glue automatic adjustment control,amount of glue automatic adjustment with the produce speed, in automatic mode, you can also get in manual tuning.

※Technical parameters:

1、the highest design speed:200m/min

2、the Max. width:2200mm

3、air source system:0.4—0.6Mpa

4、operation direction:left or right(determined by customer’s factory)

※Roller diameter parameters:

1、glue roller:¢269mm doctor roller:¢142mm

2、press paper shaft:¢155mm

3、 over paper roller diameter:¢110mm

※Powered motor parameters:

1、glue roller initiative motor:3KW 380V 50Hz Continuous (S1) working standard

2、glue adjustment reducer: 100W 380V 50Hz short(S2)working system

3、pressure roller gap adjustment motor: 100W 380V 50Hz short(S2)working system

4、glue pump motor: 2.2KW 380V 50Hz Continuous (S1)working system

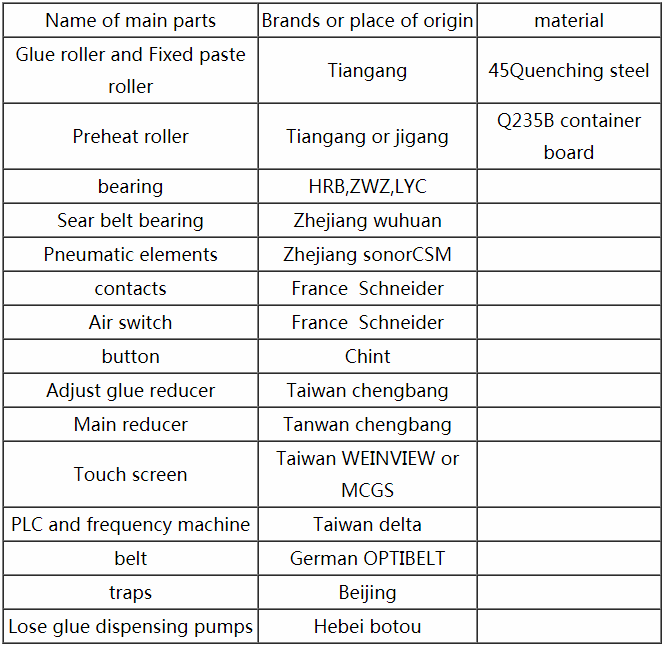

※Mainly purchased parts, raw materials and origin:

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Factory wholesale Manual Operate Corrugated Sheet Gluer - Glue machine GM-20 – Xinguang , The product will supply to all over the world, such as: Johannesburg, Oman, Lyon, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.